laser-drawing resin 3d printer

Updated on March 16, 2018

In this AmeraLabs post we will dive into what is resin printer calibration. You volition learn the key things you need to know before running your calibration procedure.

Core settings

The goal of resin 3D printer calibration is to balance these three core settings:

| | | |

| Exposure time of a unmarried layer | XY resolution (i.due east. which is pixel or laser spot size) | Layer height (Z resolution) |

Exposure time of a single layer.

The nearly of import parameter is exposure fourth dimension of a single layer. It defines lite exposure duration for a unmarried layer of an object that you lot are trying to print. This term applies to DLP and LED/LCD based 3D printers, because with such equipment unabridged layer is exposed whereas SLA printers' light amplification by stimulated emission of radiation "draws" each layer. For laser-based printers this notion of "exposure time" does not utilise directly every bit in these printers you can adjust laser ability and laser speed. Y'all can increment 3D resin light exposure with laser either past increasing power or by slowing light amplification by stimulated emission of radiation down.

Incorrect exposure is one of the major reasons why resin prints fail. Apart from such obvious reasons as loss of intricate details and dimensional accuracy, incorrect exposure settings volition effect in other distinct problems. Also long exposure settings will typically result in the following issues.

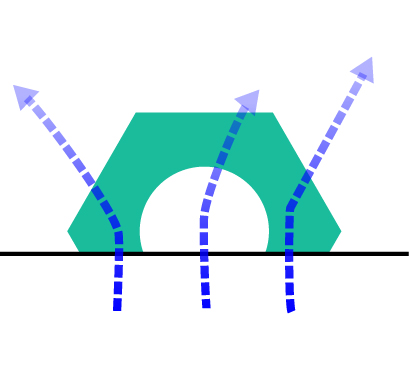

| | Haemorrhage of lightWhen lite penetrates and cures material besides deeply. It will result in loss of details and loss of dimensional accuracy in Z axis. Small features of your print will come out bigger than expected. If you discover such outcome shorten your exposure (cure time) settings. After press another resin printer calibration impress, evaluate the divergence and adjust your settings again, if needed. |

| | Scattering outcomeWhen light'southward straight trajectory deviates from intended one resulting in polymerization in undesired directions. Commonly that happens due to the lack of calorie-free blocking pigment in 3D press resin. Too long curing times may magnify this scattering effect. Information technology volition also result in loss of details and dimensional accurateness in Z also as in XY axis. You can start fixing this by reducing your exposure settings and/or adding more than light blocking paint. In most cases information technology is difficult to solve scattering effect issue without irresolute the 3D printing fabric type. |

In regards to too short exposures you will terminate up having the following bug.

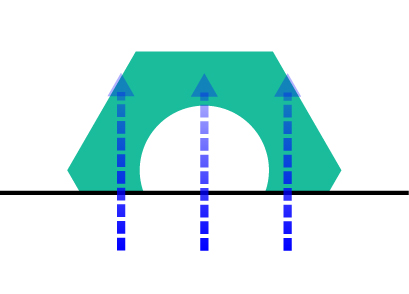

| | Under-cure eventInformation technology will typically reveal itself as layer delamination in the center of the part due to poor layer adhesion and will consequence in part or even full model stuck to the bottom of the resin tray. You can also detect serious loss of intricate details. They will come out smaller than expected, or absent-minded at all. Try to increase your exposure settings. After reprinting your examination impress, pay attention to the quality of small features. |

| | Poor adhesion of the model to the build platePoor adhesion of the model to the build plate. It can even upshot in model falling down and damaging your resin tray. The most typical effect is to see thick layer of 3D press resin cured on the bottom of the resin tray and nothing on the build plate. Increment exposure time of your kickoff layer. Get in effectually 10 times longer than your normal layer cure time. |

Information technology is not possible to characterize exposure time parameter on its ain. Exposure depends on and is a result of the rest of the factors. Then let'due south overview them one by i and see how they affect exposure fourth dimension. At the end nosotros will take a expect at other causes that influence it, but are not that meaning.

Resolution (Ten and Y axis)

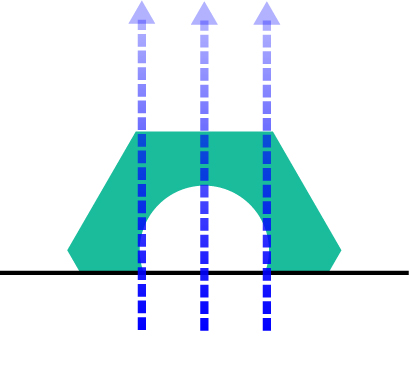

XY resolution is the size of an individual pixel for LCD/LED and DLP systems and light amplification by stimulated emission of radiation spot diameter for SLA laser systems. More often than not, XY resolution is fixed for LCD/LED and SLA systems, so yous practice non have to worry nigh exposure changes due to XY resolution adjustments. If y'all own DLP projector with adaptable resolution, it tin significantly touch your exposure times. So, you lot have to continue that in listen when running your resin printer calibration. When y'all move your projector up, you decrease your build surface area, which means that entire output of lite source (in mW) is concentrated in smaller area (cm2), therefore, your mW/cm2 increases. Consequently, your 3D resin will become more lite energy, which will result in shorter exposure times and faster chemic reaction. Opposite applies when you increase projector altitude from the resin tray. When doing this entire output of light is concentrated in a bigger expanse, your mW/cm2 decreases and resin will get less energy per square unit. That volition result in longer exposure times and slower chemical reaction.

Layer height (Z resolution)

Layer summit determines the thickness of a single layer of an object that you are printing. It is and then chosen Z resolution. You can choose from the most mutual layer heights which are 30μm and 100μm, simply if you demand extremely high quality and smooth surface, you tin also aim for 20μm. Anything in betwixt these numbers is also completely fine, merely not very common. You lot should also go on in listen that practical departure between 50μm and 20μm with well mechanically tuned automobile is negligible, whereas difference in 3D press time is huge.

It is very difficult to come up with some sort of rule for exposure time changes regarding layer changes. Intensity of calorie-free passing through a media diminishes exponentially. That existence said, absorption properties of 3D resin and its components determine the relation between exposure duration and layer thickness, which is not linear. However, here at AmeraLabs nosotros use a rule of thumb that we will share with you and which you are welcome to apply. If you go downwards below 75-100μm layer height and keep XY resolution abiding, for a 50 % layer reduction you should lower exposure by 25%. This rule is a bit subjective and in some cases correct exposure can exist even shorter, only it is a practiced starting signal.

l% lower layer peak = 25% lower exposure

How oftentimes should yous run resin printer scale process?

Apart from calibration of 3D printer correct after the purchase, there are quite a few occasions, when it is highly recommended to re-run calibration routines.

When changing 3D printing resin

If you change your 3D resin make, it is besides a good idea to re-run calibration procedures. Each brand of 3D resins is very different in terms of reactivity and pigment/dye concentration. With some 3D resin brands you lot should repeat resin printer scale even subsequently opening a new bottle, because you rarely know when it was manufactured and if well-established quality balls procedures were used. At AmeraLabs each lot of our materials is run through enormous scientifically-proven testing procedures with various resin 3D printers in society to sustain identical operation each time.

Every 3–vi months

Light source of 3D printer is aging. No affair if it is a laser, DLP/UV projector or LED – its ability decays equally time goes by. To compensate that we recommend to periodically rerun calibration procedures. However, information technology is hard to specify verbal frequency, as it depends on how oftentimes y'all print and what type of lite source you have. Therefore, if you print for your own needs, it is fine to review your light source status once in 3 to 6 months. If yous see some visible changes in your printing quality (perhaps your light source is decomposable faster than expected), y'all should rerun your calibration procedure. Of form, if yous decide to completely change your low-cal source, extensive scale is a mandatory step to obtain decent printing results.

What's next?

Finally, to ease the stress of resin printer calibration we take created AmeraLabs Towncalibration test print that is available for everybody to download. Most chiefly, it is packed with an extensive guide on how to read and interpret its various features.

If you need more than help, experience free to drop u.s. every bit an electronic mail.

Read other articles:

- The Beginner's Guide to 3D press with AmeraLabs resins

- True story of why it was so hard to choose my showtime 3D resin

- 10 reasons why you get unexpected horizontal lines on your 3D printed parts

- Zipper Layer in SLA 3D printing: what you need to know

Don't forget to browse our shopas we constantly add new and exciting products!

What tips practice you accept for calibrating 3D printers?

Source: https://ameralabs.com/blog/key-things-calibrating-resin-3d-printer/

0 Response to "laser-drawing resin 3d printer"

Post a Comment